- Homemade 3d cad mouse how to#

- Homemade 3d cad mouse driver#

- Homemade 3d cad mouse full#

- Homemade 3d cad mouse professional#

This can be done by navigating to Windows Control Panel > Add or Remove Programs > ArcGIS Desktop and click on the 'Change' button.

Homemade 3d cad mouse driver#

Windows XP SP2 or VISTA 32-bit or 64-bit operating systemģDconnexion SpaceNavigator device driver version 3.6.11 or later The device is a new generation 3D navigation device that is affordable and capable of controlling movement in six degrees of freedom: translation in x, y, z, and rotation in x, y, z.

Homemade 3d cad mouse professional#

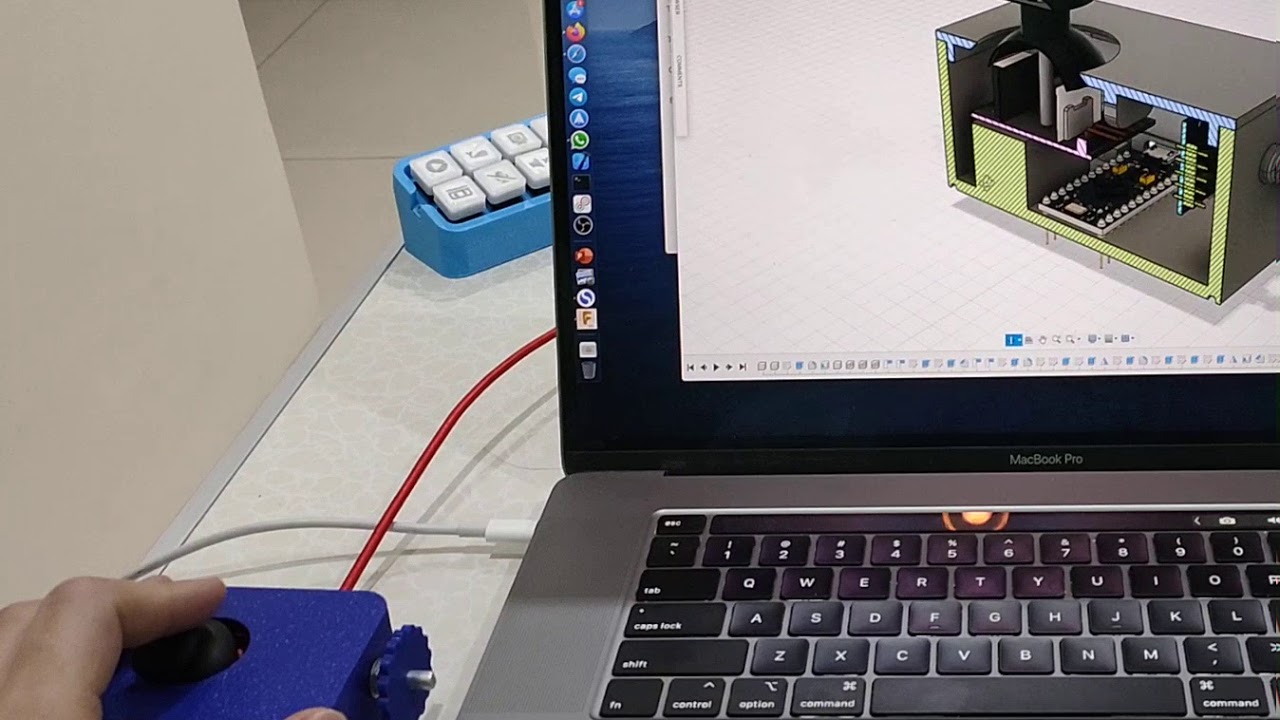

The 3Dconnexion SpaceNavigator plug-in for ArcGIS 9.2 Service Pack 2 and later versions (9.x) allows both the Standard and Professional editions of the 3Dconnexion SpaceNavigator device to be used with ArcMap, ArcMap with Dynamic Map Display, ArcScene, and ArcGlobe.įigure 1: The 3Dconnexion SpaceNavigator device

Homemade 3d cad mouse how to#

Instructions provided describe how to set up 3Dconnexion SpaceNavigator to work with ArcGlobe, ArcScene, and ArcMap.

It can also be used to increase productivity for 2D display.

The 3Dconnexion SpaceNavigator device provides the ease of navigating in the 3D display. Finished by placing a second piece of 24″ x 24″ MDF board on top and screwed everything together.How To: Set up 3Dconnexion SpaceNavigator Device for ArcGlobe, ArcScene, and ArcMap Summary For the seat, I raised it by placing eight pieces of 2 x 4, two per corner and stacked. I fixed the pedal rake angle by mounting the wood for the pedals below the pipe instead of above. In my build, the pedal rake angle was too steep and the seat was too low for me. Have a seat and check your view, hands position and feet position for the pedals. Position your steering wheel, pedals, and seat to your rig. Have a look as to what to change in order to meet your needs. Hardware positioning, initial view test & adjustments – 1 hour 45 minutes Same as PVC, only this time also use the brackets.į. Essentially this should give you an idea of what to do, check any imperfections on the cuts, and have an idea of what to change or modify. Simply put all PVC together without any screws or glue. If you can have it cut at the hardware store, it will be easier. A circular saw will do the trick for this one. Same procedure as PVC, only this time its wood. A miter saw will definitely cut cutting time and make better cuts, but I would recommend going that way if you can borrow one or plan to get one for future use, unless you have money to spare, in which case, why not get a pre-built rig? If possible, have another person holding the pipe while you cut, that way the vibrations won’t unsettle the pipe while cutting it. Not the ideal way of cutting it, but it did the job for me. That way if a small mistake occurs you won’t be left with a short pipe section, if it happens. Plan them so that a waste is left after cutting them all. Try not to use the whole pipe for the pieces. I had them cut at the hardware store in half and then made a plan on which dimensions to cut per pipe. One tip to cut the PVC pipes: typically they are sold as 10′ pipes. Also something to measure is a must, other wise how are we suppose to know where to cut? I had to acquire the power tools since now I am a grown man and have to get everything by myself, so keep that in mind if you don’t have the tools. This is the minimum of materials we will need in order to make this rig. – 12 PVC brackets (to hold the MDF boards to the rig) Before getting into the actual build, lets make a list of materials: Now, how about actually building it? I will cover that part. Ok, so finally decided to have a dedicated rig for racing? Got the space, but what about money? Some rigs could be way above our budgets, so building one could be an alternative, but what about the design and time? Don’t worry, a good samaritan has made the design for us and, best of all, available to all of us. This blog will only describe my experience during the building and testing so that anybody could have an idea of what to do. Some modifications were done to the design in order to meet my needs, but ultimately trying to keep the original concept intact. The discussion regarding the design and build can be found here.

Homemade 3d cad mouse full#

Before starting I want to give full credits to simul8r for the design and plans for the cockpit.

0 kommentar(er)

0 kommentar(er)